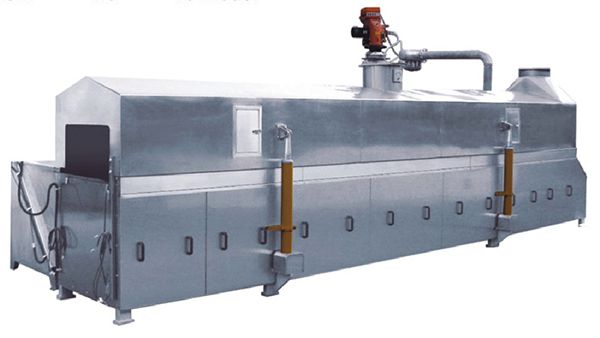

Deep Oil Fryer Series Products

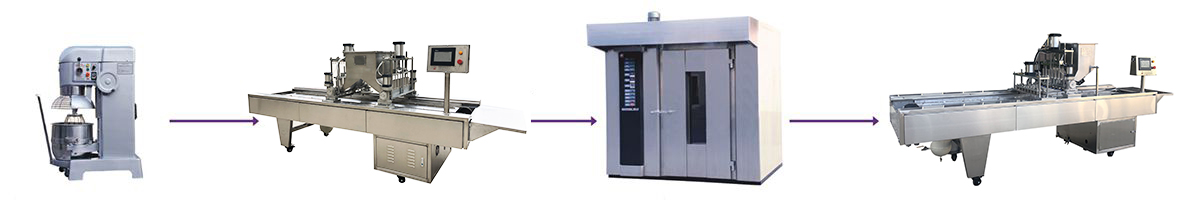

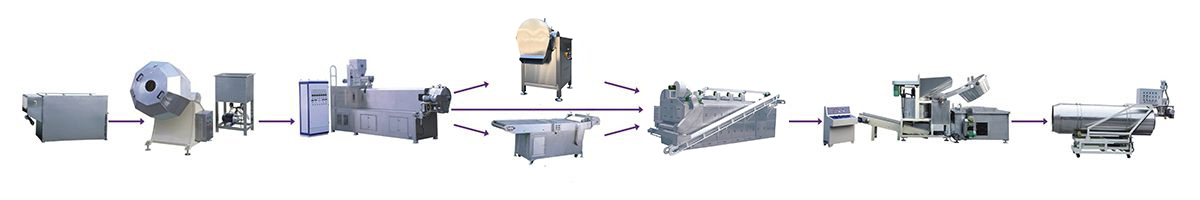

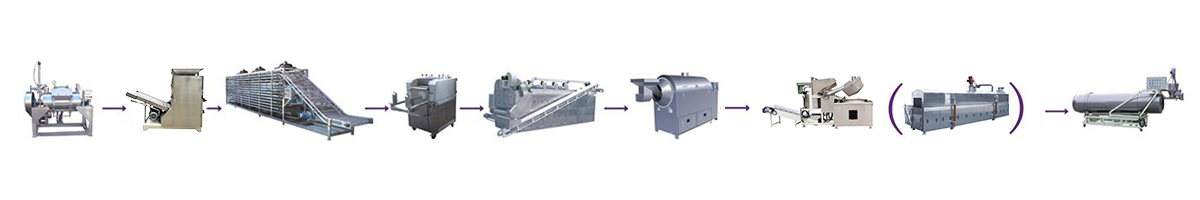

Huaxing series frying machine is divided into batch type fryer and continuous fryer. It's suitable for different kind of material and different capacity of customers' needed.

Which batch frying machine is divided into 5 types, respectively have the single frying basket standard output, single frying basket large output, single frying basket saving energy standard output, single frying basket saving energy large output and double frying basket batch fryer. All batch fryers are matching with de-oiling system and automatic discharge system. Customers can choose automatic feeding into the fryer for supporting use, to achieve more automation.

Continuous fryer for different kind of fried product, the inside structure is divided into single-layer continuous fryer, double-layer continuous fryer, fresh potato chips special fryer. In order to match with different capacity, there are different widths and lengths of continuous fryers can be customized. Welcome to contact with us.

Welcome to contact us for more about our commercial deep fryers.

HX’s industrial fryers are highly efficient and easy operated, which enables batch fry or continuous fry of varied leisure snacks.

Optional for diesel or natural gas heating; frying time and temperature can be set and adjusted on control panel.

T300S batch fryer is specially designed for second frying, thus to meet customer’s needs.

LX and FH series are mainly used for continuous frying for varied snacks.

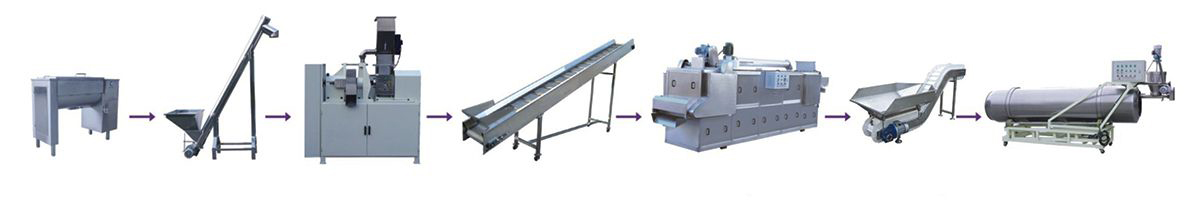

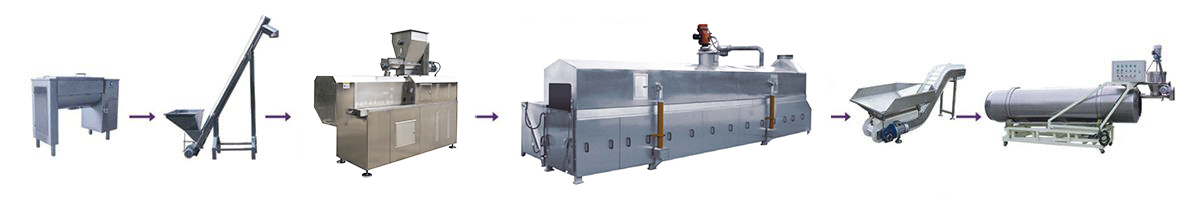

Continuous fryer, together with feeding and deoiling system, is an automatic frying system. HX can produce tailor-made fryers as well.