Stackable Potato Chips Production Line / Complex Potato Chips Production Line

Stackable potato chips production line is a fully automatic line using big percent potato power as raw material, which can be processed into crisp fried chips with unitive shape. With a returning system to recycle the leftover material, the raw material use efficiency is very high. The stackable potato chips are with consistent shapes, so it can be packed by using paper-column and pouch, the popular chips brand "Pringles" and "Lays". The stackable chips are with dense fragrance and elegant shapes. This production line combines foreign and domestic advanced techniques, with high automation and convenient operation.

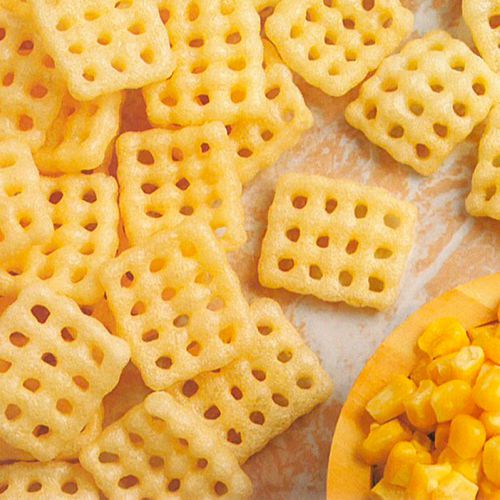

Samples

With the same form and strong aroma, parabolic potato chips can be packaged in paper tubes or bags. Currently, the most popular brands are Pringles and Lays.

Main Processing Steps

Our stackable Natural Potato Chips Production Line is a perfect line to produce potato chips from mixing, feeding, sheeting, forming, frying, flavoring, stacking to conveying.

Wet mixer is for mixing raw material with water.

Parameters

- Capacity: 250-300kg/hr

- Power: 12kW

- Dimension: L-2220mm,W-1390mm,H-1220mm

Request a Quote

The sheeter is for make material into required dough sheet in one time. Solid roller achieve extraordinary sheeting effect. Sheeting the material become dough sheet with require thickness.

Parameters

- Capacity: 250-300kg/hr

- Power: 19.25kW

- Dimension: L-3300mm,W-1500mm,H-2450mm

Request a Quote

Forming machine is for get the chips shape by roller cut of chips mould.

Parameters

- Capacity: 250-300kg/hr

- Power: 4.5kW

- Dimension: L-3380mm,W-1560mm,H-2000mm

Request a Quote

Excellent De Oiling Function

The de oiling function is to remove excess oil from the chips after frying, thus the chips to be more crispy and with an extremely less oil content. Even if stored for a long time, there will be no oily smell exist.

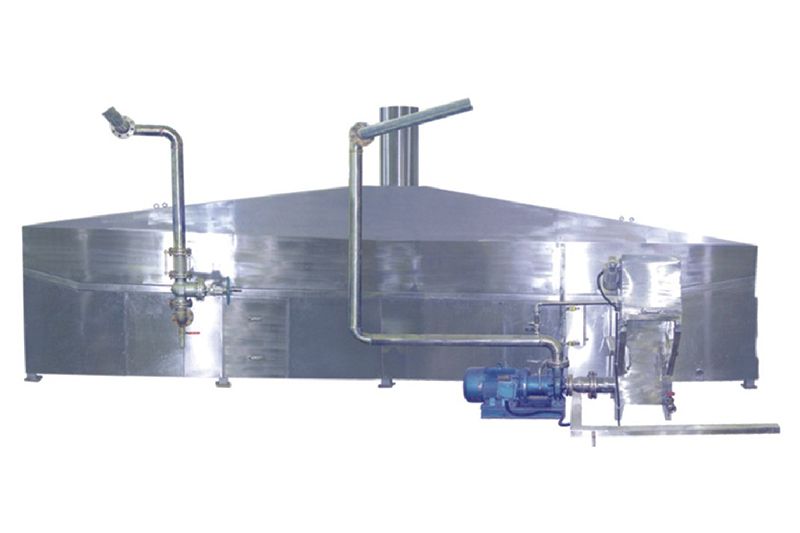

Heating

Instead of electronic fryers, we use gas or diesel oil fryer for production, which of the heating source can helps to ensure the required frying temperature. In this way, the dough sheets fried by the continuous fryer will be more crispy.

Parameters

- capacity: 200-250kg/hr

- Power: 30kW

- Dimension: 9100×1800×2430mm

Request a Quote

The seasoner with conveyer is for flavoring the chips after frying, it is used for add some seasoning powder into the chips to enhance its flavor. It makes the chips taste more excellent.

Parameters

- capacity: 200-250 kg/hr

- Power: 8.6kW

- Dimension: 4300×2200×1800mm

Request a Quote

HX has more than 40 years of experience in making snack food machinery, specializing in developing, manufacturing and marketing standard and customized processing lines for snack and potato chips processing. Dedicated to providing complete solutions of your snack manufacturing requirement from A – Z, we provide better technical support for our customers to produce high quality products by designing and building customized processing lines. With extensive research and development, we manufacture unique and advanced production lines and equipment, such as batch fryers, continuous dryers, seasoning machines. We are committed to meeting varied requirements from our customers and embrace new challenges as our market develops and diversifies with the same commitment for decades to come.