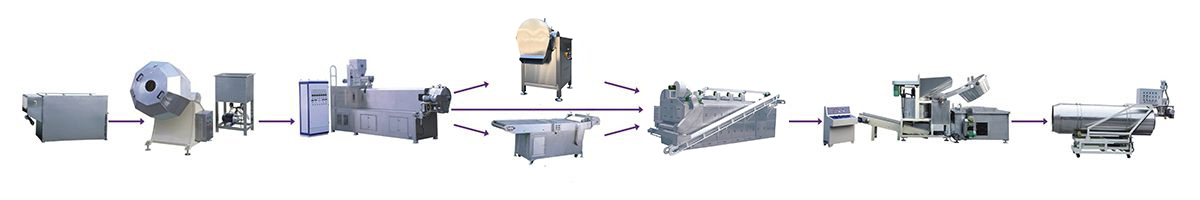

Extrusion System Production Line of Snack Pellets

Extrusion systems production line of snack pellets can be used with a very wide range of raw materials such as potato starch, potato powder, tapioca, wheat flour, etc. This production line is consist essentially of several machines in different functions as a completed production line in actual operation. The main machine of this production line is the JY-pellet extruder which is with 2 dimensions for small or big scales of extrusion processing as customers’ selection. We could also re-adjust the design and function for customers if necessary.

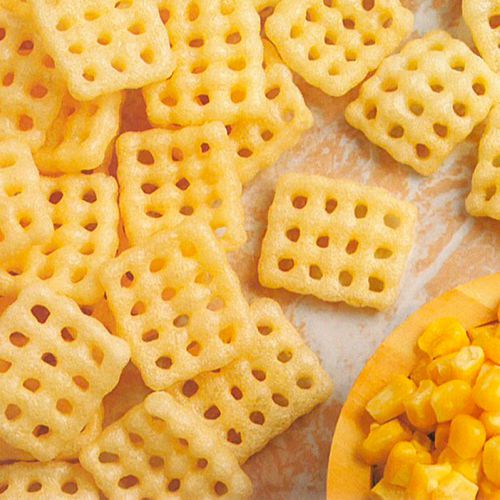

Samples

Main Processing Steps

Extrusion system production line of snack pellets is a complete production line from screening, wetting, extruding, slicing/cutting, double drying, frying and flavoring.

SF screening machine is used to screen the material to remove the impurity.

Parameters

- Capacity: 5000kg/day

- Power: 0.55kW

- Dimension: L-1830mm,W-720mm,H-1050mm

Request a Quote

SL wetting machine is used to wet the powder with water and get ready for extruding.

Parameters

- Capacity: 140kg/hr

- Power: 1kW

- Dimension: L- 1750mm, W- 1050mm, H-1620mm

Request a Quote

As the main machine of extrusion system production line of snack pellets, the pellet extruder is mainly used to produce pellet of varied shapes by different shapes of die. Snack extruder has a capacity of about 60kg/h with a dimension of 3450*930*2340mm.

Parameters

- capacity: 60 or 120kg/hr

- Power: 0 or 45kW

- Dimension: 3450×930×2340mm(S)or5200×1250×2500mm(B)

Request a Quote

After extrusion, pellet slicer will be applied to cut extruded materials directly at round chips.

Parameters

- Capacity: 60Kg/hr

- Power: 1.5kW

- Dimension: L-750mm,W-600mm,H-1050mm

Request a Quote

JYX angle cutting machine is also applied after extrusion process. Different from chip slicer, JYX angle cutting machine can be used to cut tube type extruded material into 45° bevel angle ones.

Parameters

- capacity: 60kg/hr

- Power: 1.5kW

- Dimension: 2860×700×1200mm

Request a Quote

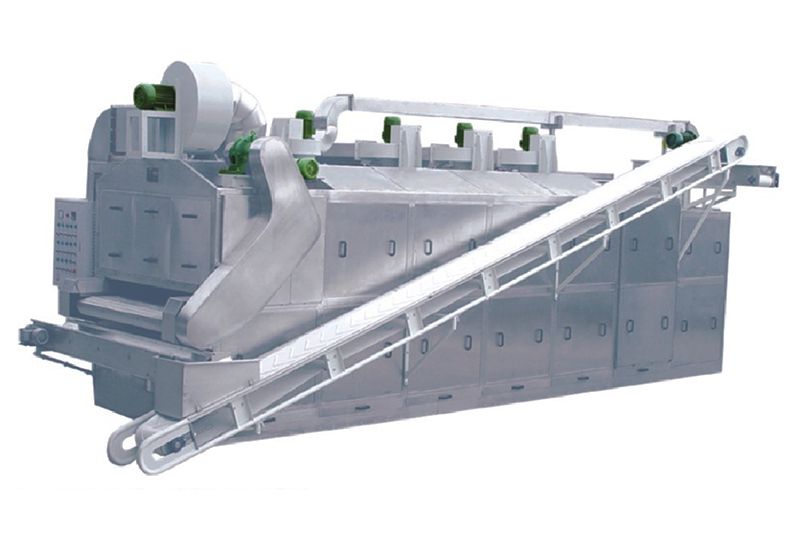

3600S dryer uses hot air circulation to reduce the moisture from materials. Heating function can be selected by gas heating, diesel oil heating or steam heating, which enjoy unparalleled effect to electric heating. Besides, HX specially designed the dryer for a better heat circulation, which makes the food more crispy.

Parameters

- capacity: 200-250kg/hr

- Power: 12kW

- Dimension: 9200×3130×3042mm

Request a Quote

300S batch fryer is equipped with centrifuge de-oiling system and discharge conveyor. It is use to fry the pellets. Frying temperature and time adjustable. It is one of the hot sale product from Huaxing.

Parameters

- capacity: 120kg/hr

- Power: 4kW

- Dimension: 4550×1980×2020mm

Request a Quote

NZ180 continuous seasoner is used to flavor the snack after frying, It is fit for add some seasoning powder into the chips to enhance its flavor. This model fit for dry flavor powder only. It makes the chips taste more excellent.

Parameters

- Capacity: 120-200kg/hr

- Power: 1.75kW

- Dimension: 3200x930x2050mm

Request a Quote

HX has more than 40 years of experience in making snack food machinery, specializing in developing, manufacturing and marketing standard and customized processing lines for snack and potato chips processing. Dedicated to providing complete solutions of your snack manufacturing requirement from A – Z, we provide better technical support for our customers to produce high quality products by designing and building customized processing lines. With extensive research and development, we manufacture unique and advanced production lines and equipment, such as batch fryers, continuous dryers, seasoning machines. We are committed to meeting varied requirements from our customers and embrace new challenges as our market develops and diversifies with the same commitment for decades to come.