(frying type)

Twin screw extruder, extruding flour and other raw materials, through a variety of different forming cutting machine to make triangle shape, fish shape, heart shape and 2D or 3D products, and the products need to be fried.

Twin screw extruder, extruding flour and other raw materials, through a variety of different forming cutting machine to make triangle shape, fish shape, heart shape and 2D or 3D products, and the products need to be fried.

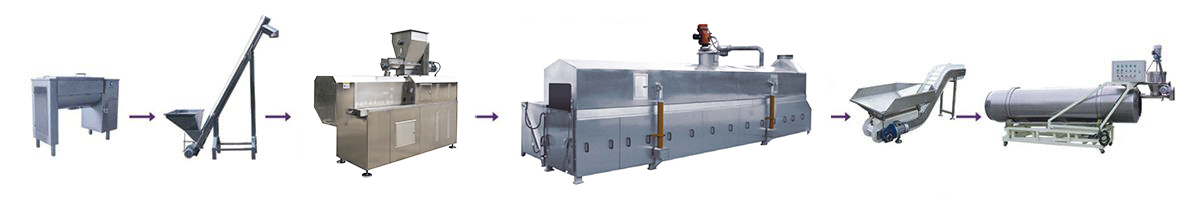

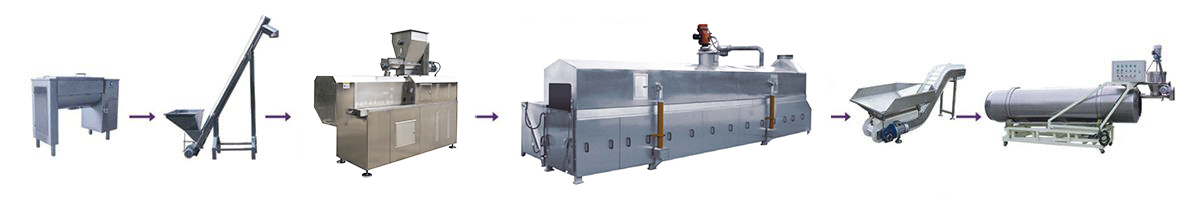

Twin Screw Direct Expansion Puff Snack Production Line (frying type) delivers multiple processing steps, from mixing material,feeding to twin screw Extruder for extruding,shaping,frying and flavoring.

Twin screw Extruder is the main machine of twin screw direct expansion puff snack production line (frying type). It is suitable for using powder as raw material. This extruder is used for extruding the raw material, and extrude the puffed snacks by different shape of die.

Parameters

LX continuous fryer with external heating system and basic filter. Different inner structure and length machine models are special designed for different snack products. It's component is consist of frying tunnel, heating exchanger, oil tank, pipeline, oil pump and basic filter.

Parameters

LX200 continuous seasoner is one of the flavoring machine to flavor the snacks after drying, this model can connect the oil spray tank for flavoring. It not only fit for spray flavoring oil but also powder. It makes the chips taste more excellent.

Parameters