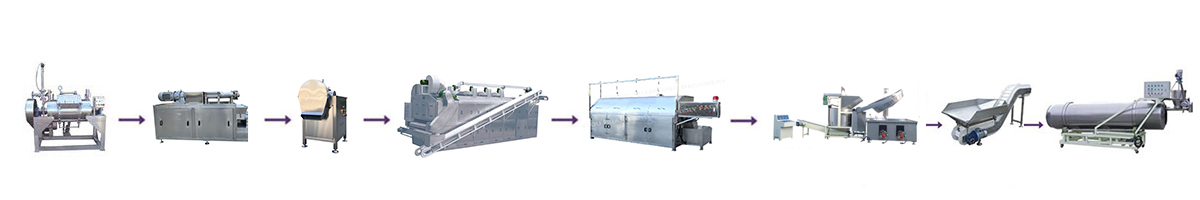

Steam Cooking Extrusion System Production Line of Snack Pellets/Prawn Chips Production Line

Steam cooking extrusion systems production line of snack pellets is fit for those raw material like tapioca starch, corn starch, wheat flour, etc. In short time, cooking and mixing those materials by steam into sticky dough. And then press it into dough sheet with average thickness and surface. After cooled, it can be cut into various shapes, and then dry and make into snack pellets with different shapes. At last, deep oil fry them into prawn cracker.

Samples

Main Processing Steps

As the main machine of steam cooking extrusion system production line of snack pellets/ prawn chips production line, steam cooking machine uses steam to cook raw materials. HX’s upgraded steam cooking machine is also available for you, which enjoys better cooking technology and higher level.

Parameters

- Capacity: 180-240kg/h

- Power: 11kW

- Dimension: 2030×770×1540mm

Request a Quote

Knead the dough and get forming to make the dough sticky.

Parameters

- Capacity: 250-300kg/h

- Power: 7.5kW

- Dimension: 1520 x 660 x 1090mm

Request a Quote

Pellet Slicer will be applied to cut the dough stick directly at round chips.

Parameters

- Capacity: 60kg/h

- Power: 1.5kW

- Dimension: 750x600mmx1050mm

Request a Quote

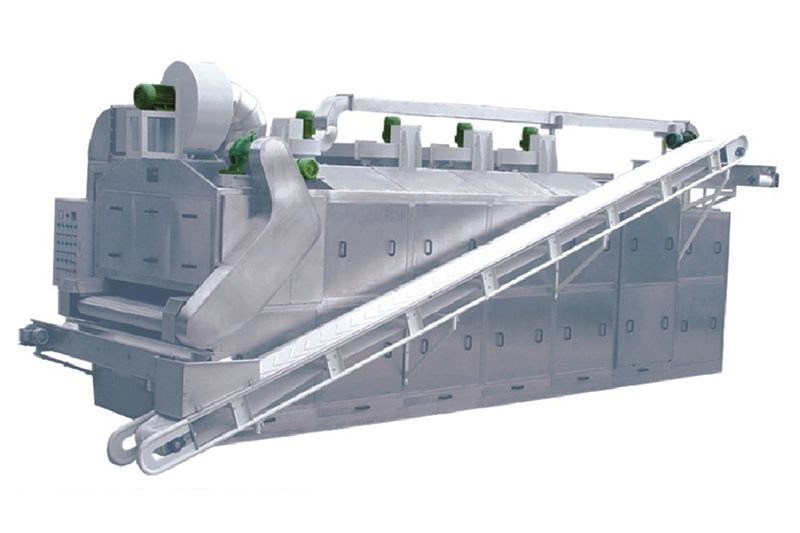

3600SL dryer uses hot air circulation to reduce the moisture from materials. Heating function can be selected by Gas heating, Diesel oil heating or Steam heating, which enjoys unparalleled effect to electric heating. Besides, HX specially designed the dryer for a better heat circulation, which makes the food more crispy.

Parameters

- Capacity: 200-280kg/h

- Power: 12kW

- Dimension: 11200x3130x3042mm

Request a Quote

The second times drying machine.

Parameters

- Capacity: 250 kg/ Batch

- Power: 2kW

- Dimension: 3350x1350x2160mm

Request a Quote

600S batch fryer is equipped with centrifuge de-oiling system and discharge conveyor. It is use to fry the pellets. Frying temperature and time adjustable. It is one of the hot sale product from Huaxing.

Parameters

- Capacity: 240kg/h

- Power: 4.05kW

- Dimension: 5500×2120×2380mm

Request a Quote

LX200 continuous seasoner is one of the flavoring machine to flavor the snacks after drying, this model can connect the oil spray tank for flavoring. It not only fit for spray flavoring oil but also powder. It makes the chips taste more excellent.

- Capacity: 150-300kg/h

- Power: 1.75kW

- Dimension: 4020x930x2050mm

Request a Quote

HX has more than 40 years of experience in making snack food machinery, specializing in developing, manufacturing and marketing standard and customized processing lines for snack and potato chips processing. Dedicated to providing complete solutions of your snack manufacturing requirement from A – Z, we provide better technical support for our customers to produce high quality products by designing and building customized processing lines. With extensive research and development, we manufacture unique and advanced production lines and equipment, such as batch fryers, continuous dryers, seasoning machines. We are committed to meeting varied requirements from our customers and embrace new challenges as our market develops and diversifies with the same commitment for decades to come.