Frictional extruder ----Automatic crunchy/kukure/nik nak corn snack food production line, with upgrade sieving machine,make the product more purer.

Frictional extruder ----Automatic crunchy/kukure/nik nak corn snack food production line, with upgrade sieving machine,make the product more purer.

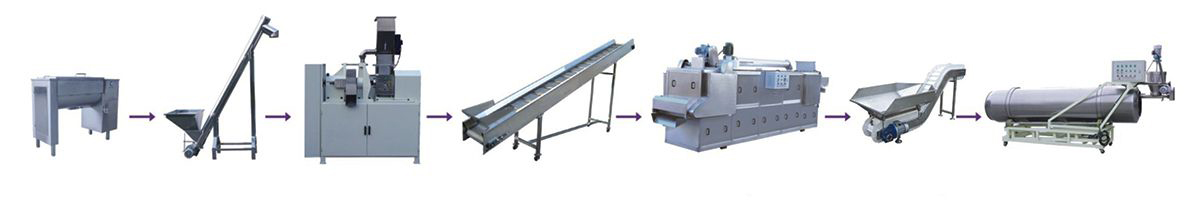

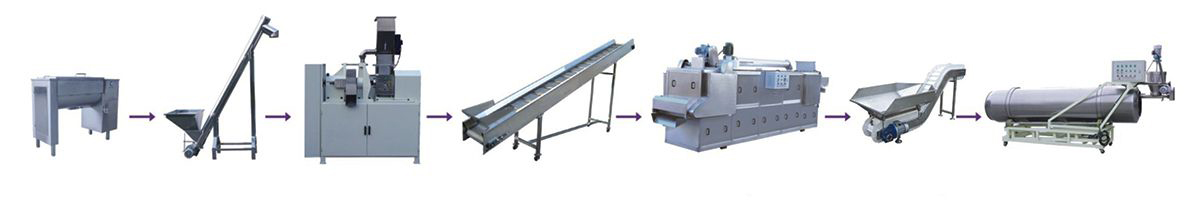

Twist snack production line delivers a complete corn snacks production process, including mixing, feeding, extrusion, conveying, drying, conveying and flavoring. It is fit for making the corn snack in stick but irregularly. The raw material is granule. After the main machine to get the shape. There are two ways for continuous processing. One way is by deep fry, another way is by hot air drying. The products look like “Cheetos” or “Kukure” snack in the market.

As the main machine in twist snack production line,the MC frictional extruder is apply to produce the twist shape snake by frictional extruding the mixed material. The snack names "Kukure" too. The size of the product is adjustable.

Parameters

A300S drying machine is used to dry the twist snack/Crunchy Kukure snack products after frictional extruded. Which can help to reduce the moisture from snacks and make it more crispy and tasty. There is the heating system of the dryer can be choose: diesel oil heating, gas heating, steam heating. This is a high temperature drying machine, drying temperature and drying time are adjustable, it dry the products by hot air circulate. In this way, a better thermal energy storage and higher thermal efficiency will be achieved.

Parameters

LX200 continuous seasoner is one of the flavoring machine to flavor the snacks after drying, this model can connet the oil spray tank for flavoring. It not only fit for spray flavoring oil but also powder. It makes the chips taste more excellent.

Parameters