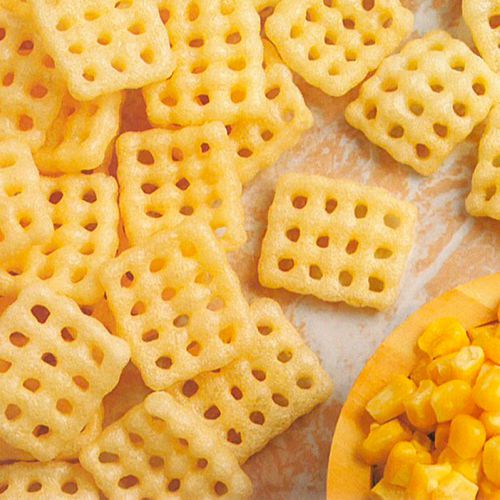

Custard cake production line is for making cup cake and other shape cake (vitellus cake), as a very popular kind of snack food, these cakes could be filled with different flavors of stuffing, after packed into proper package, the finished products could be preserved for a long time. By using different shapes of metal trays, the shapes of cakes could also be very different, but in each time of production, the cakes are in same shape and even quality for sure.

Samples

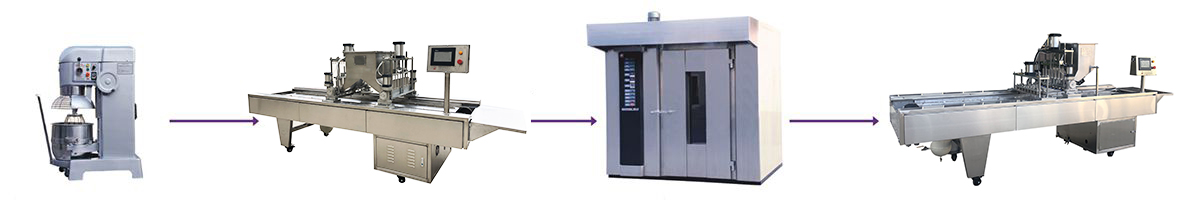

Main Processing Steps

Cup Cake Production Line delivers complete custard processing steps, including material mixing, filling mixing, cupcake batter dispensing, baking and cream dispensing.

As the main machine of Cup Cake Production Line, cake depositor (cake filling machine) is used to dispense cupcake batter, after the mixing in vertical mixing machine, into baking trays, which allows adjustable dispensing amount. Cake depositor is equipped with PLC and touch screen, which is easy operated and of high-level. It has a capacity of 8000-10000 PC/hour and a weight of 780kg.

Parameters

- capacity: 8000-10000PC/hour

- Power: 0.37kW

- Dimension: 3000×850×1400mm

- Weight: 780kg

Request a Quote

Bakery oven is also one of the key machines in Cup Cake Production Line. HX’s bakery oven is of rotary type and mainly used to bake cakes. Our rotary bakery oven has a capacity of 4500-6000 PC/hour and a weight of 1485kg.

Parameters

- capacity: 2000-2500PC/hour

- Power: 3.5kW

- Dimension: 2350×2080×2650mm

- Weight: 1485kg

Request a Quote

As one of the main machines in filled cupcake production machine, our cream depositor is actually not necessary, which is only used when baking filled cakes. It is designed to dispense fillings into baked cakes in an adjustable amount. Our cream depositor is equipped with PLC and touch screen,which is easy operated and of high-level. It has a capacity of 8000 PC/hour or 1600 8000 PC/hour and a weight of 560kg.

Parameters

- capacity: 8000-10000PC/hour

- Power: 0.37kW

- Dimension: 3000×660×1500mm

- Weight: 560kg

Request a Quote

HX has more than 40 years of experience in making snack food machinery, specializing in developing, manufacturing and marketing standard and customized processing lines for snack and potato chips processing. Dedicated to providing complete solutions of your snack manufacturing requirement from A – Z, we provide better technical support for our customers to produce high quality products by designing and building customized processing lines. With extensive research and development, we manufacture unique and advanced production lines and equipment, such as batch fryers, continuous dryers, seasoning machines. We are committed to meeting varied requirements from our customers and embrace new challenges as our market develops and diversifies with the same commitment for decades to come.